Crambe Abyssinica

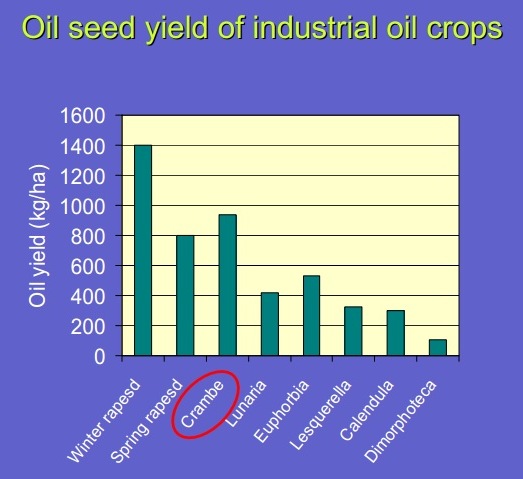

Yield

Abyssinian oil comes from the seeds of Crambe Abyssinica, a plant native to the Mediterranean area. Crambe is an oilseed crop that produces inedible oil, but its oil has a number of industrial uses.

Oil content of the grain has been shown to vary from 36-43% with a Erucic Acid content of the oil ranging from 55-60%. Grain oil content varied between 35.6 and 42.8% (mean 38.90%) for twenty-five samples analyzed from the 1996 Walpeup test project in Victoria, Australia.

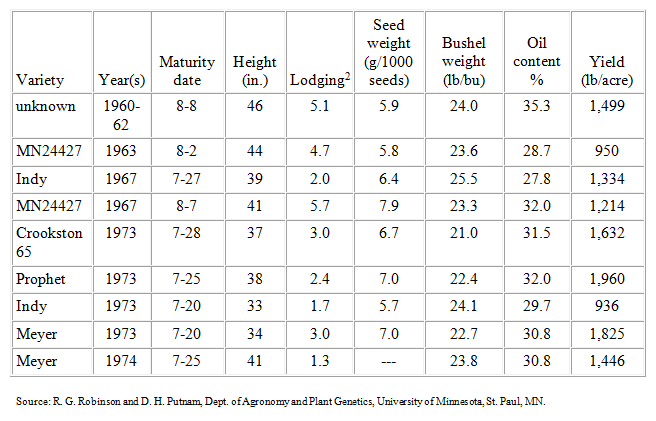

Yields vary widely from 1,125-1,624 kg/ha in Russia and 450-2,522 kg/ha in the United States. Crambe has yielded up to (2,500 lb/acre—1,133kg/acre) on small commercial fields and demonstration plots. A yield of (1,200 to 1,800 lb/acre–544 to 816 kg/acre) is more typical in commercial production fields with good management practices.

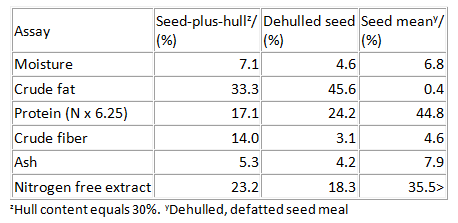

On a dry basis, whole crambe seed contained 33.9% oil, 25.2% protein, and 12.3% crude fiber. Crambe meats were high in oil 47.6% and protein 31.6% and low in crude fiber at 5.0%. Crambe hulls were low in oil 1.2% and protein 8.8% and high in crude fiber 42.6%.

The oil content is nearly double that of soybeans and 8-9% higher than rapeseed.

In other studies, the Control Line at Horsham, Victoria, Australia yielded 1234 kg/ha and in 1970 Hoag and Geiszler reported a five year mean yield in Minot, North Dakota, USA on fallow land of 1698 kg/ha. At Williston, N.D on dryland, a mean yield of 842 kg/ha was obtained during the same 1965-1969 period.

The species has the potential to provide the local farming community with an alternative oilseed crop to canola and the potential to provide industry with a new raw feedstock source.

Production costs for crambe in the Midwest are approximately the same as those for wheat and canola, except for the higher cost of crambe seed. Machinery used for tillage, planting, spraying, and harvesting crambe is similar to that used for small grains. Farmers producing small grains would not have to purchase additional machinery to produce crambe.

In 1990, crambe yielding (1,500 lb/acre—680 kg/acre) in the Midwest cost $0.10/lb-$0.22/kg to produce. Crambe production would not compete directly with domestic seed oils since it would provide a substitute for Erucic Acid extracted from imported rapeseed.

The exact prices for Crambe Oil and meal are not available, so price ranges of ($0.28-0.35/lb-$0.64-0.80/kg) for oil and $75 to $100 per ton for meal are used as best estimates by industry analysts.

Summary of crambe performance data from Rosemount, MN, 1960-1974

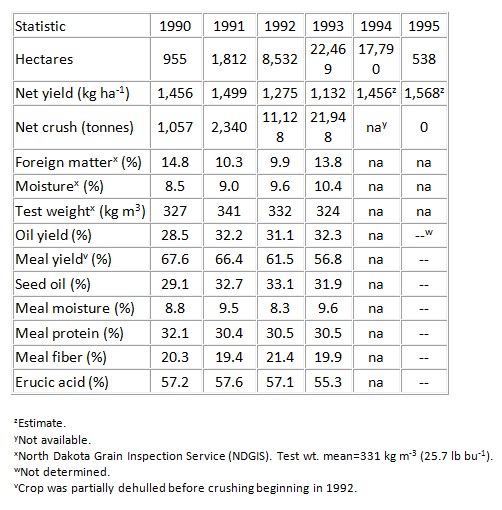

In 2002, Crambe was grown in 54 farms in the United States and was harvested on (12,320 acres/4986 hectares), with a total production of (13.3 million lb/ 6.03 million kg). North Dakota was the leading producer with 34 farms and harvested (7.5 million lb/ 3.4 million kg from 7481 acres/3028 hectares). Montana had 20 farms and harvested (5.8 million lb/ 2.6 million kg from 4839 acres/1958 hectares), 2002 Census of Agriculture 2004. USDA's National Agricultural Statistics Service no longer tracks Crambe production.

Carbon Capture

I was unable to find rates of CO2 sequestered for Crambe Abyssinica in order to qualify for carbon tax credits. If you have tons per hectare per year, please send along your information and I will post it here.

Crambe production statistics from North Dakota, 1990-1995

Uses

Erucic Acid extracted from Crambe Oil is used to manufacture a multitude of industrial consumer items such as high-temperature lubricants; heat transfer fluids; surfactants and coatings; cosmetics; polyesters; plastics; nylons; corrosion inhibitors; ingredient in synthetic rubber; adhesives and waxes.

Erucic acid has an established market in Erucamide, a preferred slip and anti-block agent for polyolefin films.

High-Erucic acid content from the oil is a major attraction for this new crop, as a substitute for traditionally old varieties of rapeseed which are a major source of Erucic acid. Therefore, Crambe offers a new specialty oil for industrial applications.

Crambe, like other vegetable oils, is durable and possesses high smoke and flash points whilst retaining stability and oiliness at high temperature.

The United States uses up to 40 million pounds of high-Erucic acid oil annually mostly imported from Poland and Canada. Although rapeseed is grown domestically, Crambe oil contains 8 to 9% more Erucic acid than industrial rapeseed oil. Hence, the reasoning behind Crambe and its promotion as a new domestic source of Erucic acid.

Analyses of Crambe seed and seed meal

Crambe meal left after oil extraction has some potential as livestock feed, but it needs to be processed. Defatted Crambe seed meal can be used as a protein supplement in livestock feeds. The meal contains 25 to 35% protein when the pod is included and 46 to 58% protein when the pod is removed. It has a well-balanced amino acid content and has been approved by the FDA for use in beef cattle rations for up to 5% of the daily intake.

Description

The Crambe plant is a multi-branched annual which is closely related to rapeseed and mustard that usually grows less than one meter in height. Crambe species (of which there are several) originate mostly from the Mediterranean.

The noticeably much branched plant supports yellow-white colored flowers on long racemes. Flowers produce single greenish-brown seeds that are encapsulated in fawn colored capsules.

Under stress conditions plants may develop long tap roots, which later become conical. The leaves are oval shaped, but asymmetric. The leaf blade is approximately (4 in/10 cm. long and 3 in/7cm) wide, with a smooth surface; the petiole is channeled, about (8 in/20cm) long, and pubescent (hairy).

Crambe initially produces numerous small, white flowers in a compact group, which are later distributed on (1-2 ft/0.3-0.6m) stalks or spikes.

The plant has a short growing season of from 90-100 days

Crambe is reported to tolerate an annual precipitation of 35 to 120cm, an average annual temperature range of 5.7 to 16.2°C.

Distribution

Originally from the Mediterranean region, it has been grown in tropical and subtropical Africa and from Ethiopia to Tanzania, the Near East, Central and West Asia, Europe, the United States, and South America.

In recent years, there has been a lot of development work in the USA to find alternative uses for the oil and to increase productivity from the crop. In Australia it is still an experimental crop and it has been under testing for a number of years in the Wimmera and Mallee areas of Victoria.

Crambe is suited to the major grain growing areas of southern Australia. It requires 90-100 days from planting to harvesting and can tolerate cool temperatures and drought conditions.

In 1992, it was estimated that there were about 10,000 hectares grown in USA and production at that stage indicated that this could quickly grow to 30-40,000 ha. Since the mid-1990s, production has been chequered. In North Dakota, USA in 1996, 16,000 ha of Crambe was estimated to yield 7-9 million kg of oil.

Being related to rapeseed and mustard, it is similar to these plants and can be grown with normal cropping machinery used for oilseed production.

Planting

Crambe likes well-drained fertile soils of moderately coarse to fine texture with pH 5.0 to 7.8. Like most broad acre crops it will not tolerate heavy soils that are prone to waterlogging. This oilseed crop is a cool season one and can tolerate temperatures as low as 24°F. The crop requires 88 to 110 days from planting to maturity.

Crambe is normally sown in autumn into a fine seedbed, using a conventional seeder that plant 15-20cm rows. USA results show that planting depth is critical to obtaining a good yield. In the drier areas, it is recommended that the sowing depth be about 2-2.5 cm at a seeding rate of about 15-20kg/ha, using similar management applied to that for canola.

Planting depth is a critical factor in obtaining good Crambe yields. Seed should be planted 1cm deep in humid regions and up to 2.5cm deep in drier areas. A culti-packer seeder does an excellent job of placing the seed at the appropriate depth. A seeding rate of 10 to 20 lb/acre or 10 to 20 kg/hectare is recommended.

Although it is relatively drought-tolerant, the best yields have been obtained in moist areas. While Crambe requires adequate soil moisture during pod set and filling, a subsequent dry period as the plant matures promotes high yields.

The number of Crambe varieties available for commercial production is limited. Meyer is the only variety available in sufficient quantity for field production. Belann, Belenzian, Indy, and Prophet are other registered varieties; however, commercial seed supplies of these varieties do not exist.

Certified seed costs are generally less than $12 ha-1 for the typical 22 kg ha-1 seeding rate.

Acceptable yields have been recorded for row widths ranging from 6 to 36 in/15-75cm. However, where weeds are not a serious problem, row widths of 6 to 12 in/15-25cm. give highest yields. Crambe planted in rows wider than 30 in. will tend to lodge, making harvest difficult.

Weed competition can reduce Crambe yields significantly. Some of the weeds that may cause difficulties are pigweed, foxtail, smartweed, lambs quarter, ragweed, and kochia.

The crop will not tolerate heavy clay, wet or waterlogged soils. Seed can be treated with a fungicide or soaked in water at 140°F for 20 minutes or at 130°F for 30 minutes to reduce problems with Alternaria brassicicola.

Crambe should be grown in isolation to canola to minimize cross-contamination. Usually cross-pollination with canola is not a problem if correct management practices are adhered to.

Diseases and Their Control

The most serious disease in Crambe is caused by Alternaria Brassicicola. This fungus causes darkening of the seed and stems, and reduces seed germination. Crambe is also susceptible to turnip mosaic virus. Use of high-quality seed is the best defense against disease problems. The seed can also be treated with a fungicide or hot water (as described in the section on seed preparation) prior to planting.

Aphids can also attack the crop and young plants are very attractive to slugs so some protection will often be needed.

Fertilizing

Phosphorus and potassium recommendations for small grains are usually adequate for Crambe. Soils showing an option test in phosphorus and potassium, approximately (45 lb/acre or 9.2kg per .45 hectare) of P2O5 and (80 lb/acre or 16.3kg per .45 hectare) of K2O are recommended.

Crambe also responds to nitrogen fertilizer with approximately (80 to 100 lb/acre or 16.3-20.4kg per .45 hectare) of actual N recommended. Credits for legume or manure N should be taken when appropriate. Like rapeseed, Crambe may respond to sulfur (20 to 25 lb/acre or 4.1-5.1kg per .45 hectare) on low sulfur soils.

Harvesting

Crambe is ready for harvest after all the leaves have dropped from the plant and the seedpods and branches have turned a straw color, usually 88-110 days after planting. When this color has progressed down the stems below the last seed-bearing branches the seed should be ready to harvest.

The crop is harvested with a normal combine, adjusted for the characteristic small lightweight seed. Yields vary with reports of 1200-2000kg/ha being reasonable results in commercial areas.

Crambe can be harvested with a standard combine with adjustable sieves. If the plants are standing, they should be cut (12 to 18 in or 30 to 46cm). above the soil surface. The seed should be harvested with the hulls intact. A cylinder speed of 400 to 500 RPM and concave clearance of (3/8 in/ 1cm). are recommended. The air should be set as low as possible with fan speed at less than 500 RPM, but never disconnect the fan to completely shut off the air flow.

Set the reel to move only slightly faster than the ground speed of the combine to minimize shattering. Crambe seed is small, round, and very lightweight. To prevent losses, a transport vehicle with no cracks or holes should be used, and the load should be completely covered with a tarp.

Crambe is susceptible to seed shatter and a higher risk of Alternaria Brassicicola infection if harvest is delayed until 100% the seeds change color.

Extraction

The spherical fruits bear one seed each. The seed remains in the pod or hull at harvest. Mature fruits are dry, persistent and indehiscent. They vary in color from light green to light amber brown. Crambe seeds weigh approximately (0.25 oz/8.25 gm) 1,000 seeds and have a hull content of 25 to 30%.

De-hulling improves oil extraction efficiency and facilitates the marketing of high-protein meal (>40% protein). An effective de-hulling process must meet several conditions: there must be near-complete separation of the hull from the meat (decortication) this is in order to minimize losses of oil from the meat and subsequent adsorption of oil by the hull.

Roller milling was more effective than impact milling. The optimal roller mill gap was (7/64 in/0.28 cm), and the optimal impact mill speed was 2,400 rpm generating 44.7 m/s tangential speed.

The primary products from Crambe seed include oil (around 35%), meal (64-69%) and hulls (3%).

Drying and Storage

Crambe should be dried to no more than 10% moisture before storage and should be passed over a scalper to remove trash.

Even if the Crambe seed is dry at harvest, it may contain green plant parts from weeds and grass, as well as insect parts. This wet trash can cause the seed to heat in a short time. To prevent heating, aerate the seed as soon as the bin floor is covered with 2 to 3 ft of seed. Use a minimum air flow of 0.1 cfm per bushel. Continue aeration until the moisture and temperature of the seed have reached equilibrium throughout the bin.

The fan may also be used to continue drying the seed in the bin. Bin- drying with unheated air requires a minimum air flow of 1 cfm per bushel and should not be attempted if the moisture level in the seed exceeds 20%. Seed depth in the bin should be limited to 16 ft. Heat-sensing equipment can help detect hot spots within the grain mass.

Store Crambe in clean, insect-free bins with perforated floors and a fan. A corn storage bin is suitable for Crambe.

Transportation

The vehicle in which Crambe is transported must be nearly air-tight with no cracks or holes as the seed will flow through even tiny holes, much like sand passing through an hour-glass. As a transport vehicle moves down the road, Crambe seed can be easily blown from vehicles at low speeds. The load should be completely covered to prevent such losses.

Transportation costs are high because a small amount of seed weight is hauled in a given truck load. To reduce this cost, Crambe production areas should be close to processing plants unless de-hulling is performed to remove 30% hull weight.

David DuByne is a consultant for companies entering Myanmar & agricultural commodities export broker for green coffee, honey, farm raised fish out of Myanmar. He can be reached at ddubyne (at) oilseedcrops [dot] org.