Algae

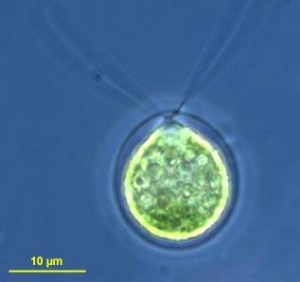

The term algae is used to collectively refer to 30,000 identified species of very simple, aquatic plant-like organisms that lack any sort of vascular system and are characterized by unicellular sexual structures. The biodiversity of microalgae is enormous and they represent an almost untapped resource.

Editors involvement with algae biodiesel is starting an algae fuel company Dao Energy in Chengdu, China.

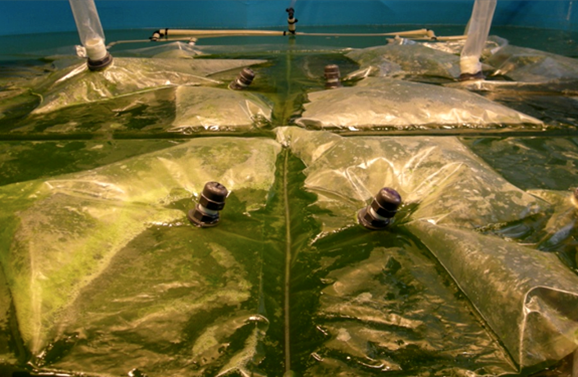

The concept was to use low cost labor and materials within China to mass produce 100% recyclable floating bag grow-out units on fish farm water surfaces, theoretically driving down installation costs to around $4-5 dollars per square meter. Installation cost is one of the bottle necks for expanding to a global commercial scale.

David DuByne's Personal Articles

Algae Industry Magazine interview about Dao Energy and the hurdles while operating an energy business in China.

Sichuan the Next Step is about Dao Energy's plans in Sichuan Province, China and some specifics of who we were partnering with.

Greenhouse Gas Sequestration by Algae – Energy and Greenhouse Gas Life Cycle Studies, Commonwealth Scientific and Industrial Research Organisation (CSIRO), reference 13 for contribution article BBI Bioenergy Australasia.

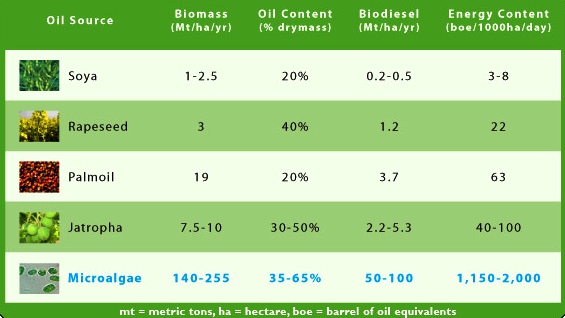

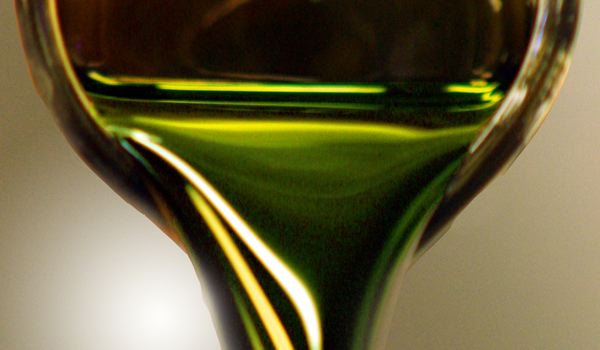

Algae Oil Yields

Algae Oil Yields

Algae can produce up to 300 times more oil per acre than conventional crops such as rapeseed, palms, soybeans, or jatropha. As algae have a harvesting cycle of 1–10 days, their cultivation permits several harvests in a very short time-frame, a strategy differing from that associated with yearly crops. Soy produces some 50 gallons of oil per acre per year; canola, 150 gallons; and palm, 650 gallons. But algae are expected to produce 10,000 gallons per acre per year, and eventually even more. Photobioreactors offer high rates of productivity, with the potential to yield 5,000-15,000 gallons of microalgal oil per acre per year. If an average yield of 10,000 gallons oil/acre/year could be achieved, the 63 billion gallon diesel demand of the US could be produced in just 6.3 million acres. Keep in mind that China has 3.8 million hectares of fish farm water surface and a floating bag grow system could offer the growing space to make that country self sufficient and export oil at maximum production rates.

An incredibly useful primer to understand in great detail the advantages and superior yield to conventional biodiesel crops. A Look Back at the U.S. Department of Energy’s Aquatic Species Program: Biodiesel from Algae

Algae Photo-Bioreactors and Grow-Out Systems

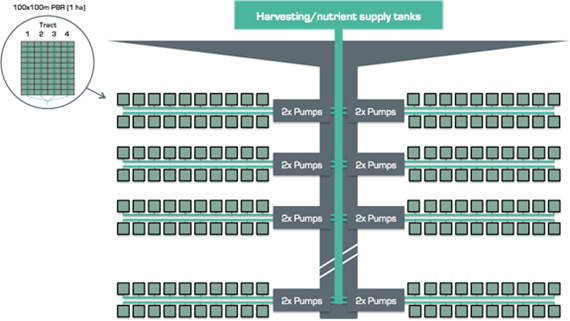

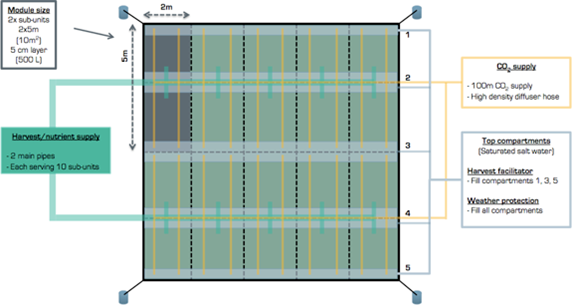

Algae can also be grown in a photo-bioreactor (PBR). Virtually any translucent container could be called a PBR, however the term is more commonly used to define a closed system, as opposed to an open tank or pond. Because PBR systems are closed, the cultivator must provide all nutrients, including CO2.

A PBR can operate in "batch mode", which involves restocking the reactor after each harvest, but it is also possible to grow and harvest continuously. Continuous operation requires precise control of all elements to prevent immediate collapse.

The grower provides sterilized water, nutrients, air, and carbon dioxide at precise rates. This allows the reactor to operate for long periods. Maximum productivity occurs when the "exchange rate" (time to exchange one volume of liquid) is equal to the "doubling time" (in mass or volume) of the algae.

Different types of Algae Photo-Bioreactors include:

Tanks

Polyethylene Sleeves or bags floating on fish farm water surfaces which Algasol Renewables produces.

Glass or Plastic Tubes

In order to commercialize and mass produce algae the installation cost must come down into the $5 per square meter range to be workable in the real world. The cheapest thing to produce when it comes to materials is a plastic bag. Algasol Renewables has the future of algae production clearly sighted in. This is the future of algal growth systems.

Consider also that as the Earth’s population increases the amount of available land for agriculture will increase, leaving less land for large algae projects aside from the deserts. The solution is to use fish farm water surfaces. Algasol Renewables is using a modular square meter bag system that connects together to create a grid.

There are 3.8 million hectares of fish farm water surfaces in China alone. That is enough space at full production to supply daily domestic demand. Imagine if every country used all of their water surface space to produce algal fuels, imports would be drastically reduced across that globe.

When imagining scale up operations whether it be open pond systems or floating bag type PBR’s, you must think in terms of size that will produce large enough amounts to supply regional areas domestically.

Algae Harvest Systems – Algae Oil Extraction

Algae oils have a variety of commercial and industrial uses, and are extracted through a wide variety of methods including using centrifuge, micro-screens, flocculation, and ultrasound. Harvesting algae is a challenge. Microalgae grow suspended in large volumes of water; at harvest time, there may be as 1,000 times more water than algae, or more.

This must be reduced to roughly a 10:1 ratio before the algae is useful for commercial applications. Costs have been high, because existing dewatering processes rely on chemicals or on heavy equipment, or both. Estimates of the cost to extract oil from micro algae vary, but are likely to be around $1.80 (US$)/kg (compared to $0.50 (US$)/kg for palm oil) by means other than ultrasonic separation.

New complete dewatering and drying systems are being tested for viability at mass scale operations. Conveyor belt D&D systems are expected to dramatically lower the current production and processing price per kilogram.

Sapphire Energy's Green Gold

The simplest method is mechanical crushing. Since different strains of algae vary widely in their physical attributes, various press configurations (screw, expeller, piston, etc) work better for specific algae types. Often, mechanical crushing is used in conjunction with chemicals. Current research and testing if focused on determining the most efficient and cost effective extraction method. The challenge here is that higher the efficiency of the extraction method, the higher is its cost. The key to commercialization is reducing the energy requirements for extraction as algae oil extraction is quite energy intensive and this is an important challenge to be recognized and addressed.

Ultrasonic: Ultrasonic extraction, a branch of sonochemistry, can greatly accelerate extraction processes. Using an ultrasonic reactor, ultrasonic waves are used to create cavitation bubbles in a solvent material, when these bubbles collapse near the cell walls, it creates shock waves and liquid jets that cause cell walls to break and release their contents into the solvent.

Expeller Press: When algae is dried it retains its oil content, which then can be "pressed" out with an oil press. Many commercial manufacturers of vegetable oil use a combination of mechanical pressing and chemical solvents while extracting oil.

Chemical Solvents: Algal oil can be extracted using chemicals. Benzene and Ether have been used and oil can also be separated by hexane extraction, which is widely used in the food industry and is relatively inexpensive. Care must be taken to avoid exposure to vapors and direct contact with the skin, either of which can cause serious damage. Benzene is classified as a carcinogen. Chemical solvents also present the problem of being an explosion hazard.

Osmotic Shock: Osmotic shock is a sudden reduction in osmotic pressure; this can cause cells in a solution to rupture. Osmotic shock is sometimes used to release cellular components, such as oil.

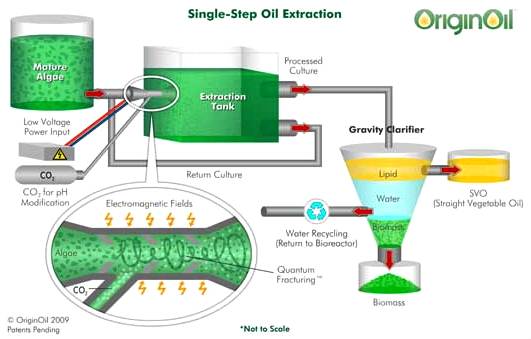

Origin Oil has created a system called Single Step Extraction™ that is chemical-free, low-energy, high-flow and low-cost. No other process can meet all these requirements. Single Step Extraction ruptures tough algae cell walls (a process called “lysing”) – to free up oils and other valuable cellular components that downstream processes can separate out. The oil floats to the top of the water coulmn and the green matter sinks to the bottom.

The process takes advantage of the fact that algae are highly sensitive to electromagnetic waves. We’ve learned to generate precisely tuned wave patterns that cause the algae to come out of solution (or “flocculate”) and to rupture (or “lyse”).

Origin Oil's process uses long, specially-designed tubes through which the algae travels, as it gradually comes out of solution, the cells being optionally ruptured.

Algae Centrifuge Extraction

After the water and algae are separated you will get a hard paste that can then be hydraulically pressed and the oil harvested.

The amount of research on algae for biofuels is staggering and began in the 1970's. A good resource to help you follow the latest trends and technology is Algae Industry Magazine. Other resources would be the many Algae Biodiesel Associations in both the E.U and U.S: Algae Biomass Organization (ABO), National Algae Association (NAA), European Algae Biomass Association (EABA), and Biofuels Digest.

David DuByne is a consultant for companies entering Myanmar & agricultural commodities export broker for green coffee, honey, farm raised fish out of Myanmar. He can be reached at ddubyne (at) oilseedcrops [dot] org.